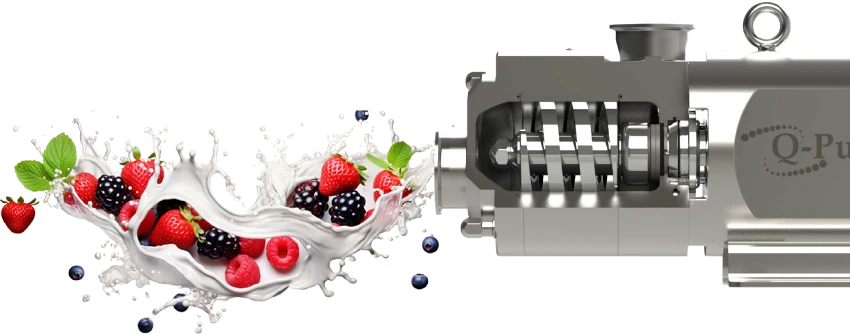

Butter Pump

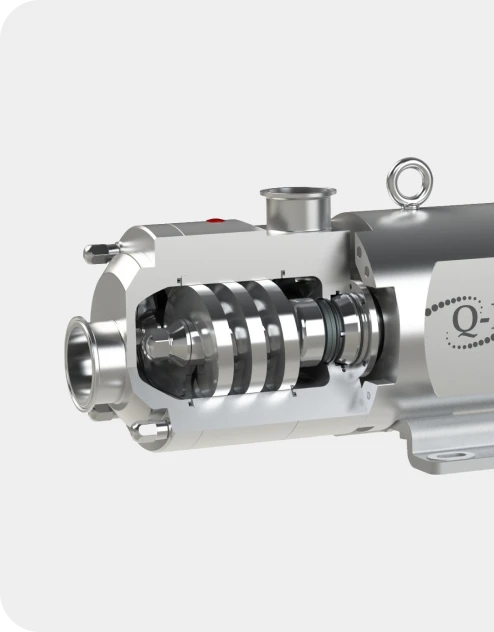

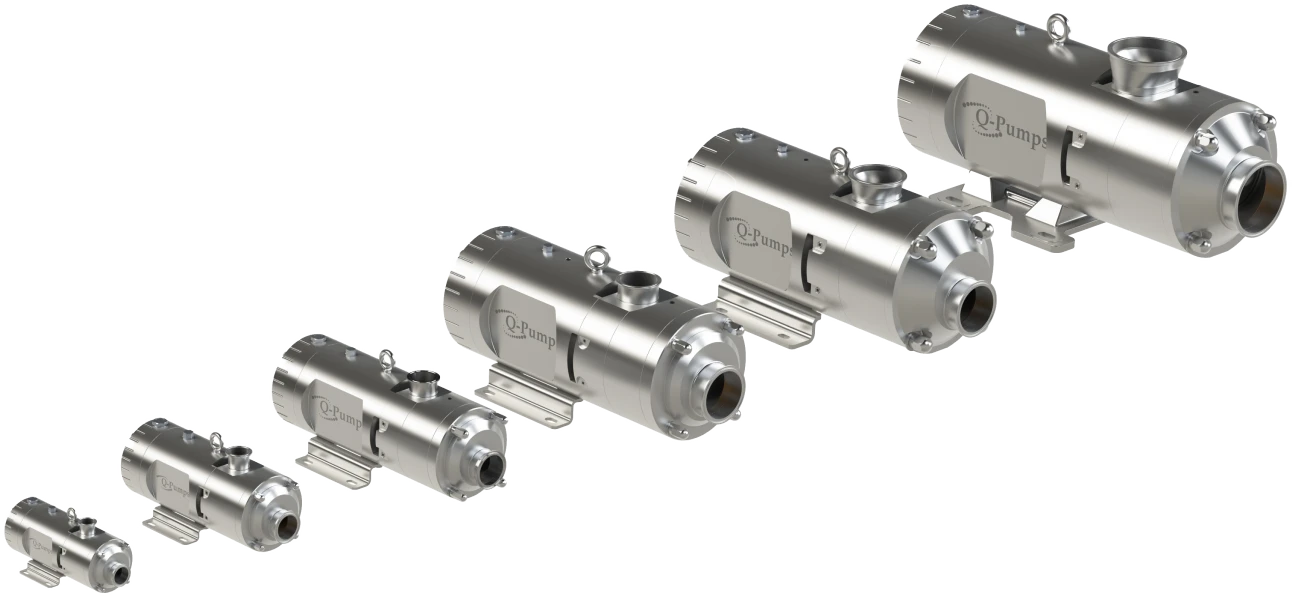

Designed for 100% sanitary conditions, the QTS twin screw pump is excellent for clean-in-place and process duties, leading to decreased time and maintenance requirements.

Case studies for the QTS pump in food industries

What our clients say

‘‘A great little pump...it is an absolute winner for us.Easy to use, gentle with product and cleans well. It's ability to suck the leftover butter from the 1,000L bags has paid for itself multiple times over’’.

Maintenance Supervisor

Challenge / Issue

Our client handles 1000L aseptic bags of liquid butter. Their challenge was recovering 100% of the butter from the bag - about 50L from each bag was being wasted due to the time and effort that would otherwise be needed to manually cut the bags open to extract the remaining product.

With multiple bags consumed in production each week, this was a significant cost saving opportunity. A pump solution was needed to pull enough vacuum to collapse the bag in order to maximise recovery of the remaining butter.

Solution and Results

Advance Pumps delivered a QTS 100 Twin Screw pump set having a 2.2kw motor with on-board variable speed drive (VSD) and external forced motor cooling fan. This achieved a very wide speed range (5hz-100hz or 145rpm-2900rpm) for more reliable control of lower product flows as well as higher speed for effective Clean In Place (CIP).

Our client is very impressed given that they have recovered enough product to pay for the pump within 2.5 months. That’s an attractive ROI!

Get the QTS pump with us

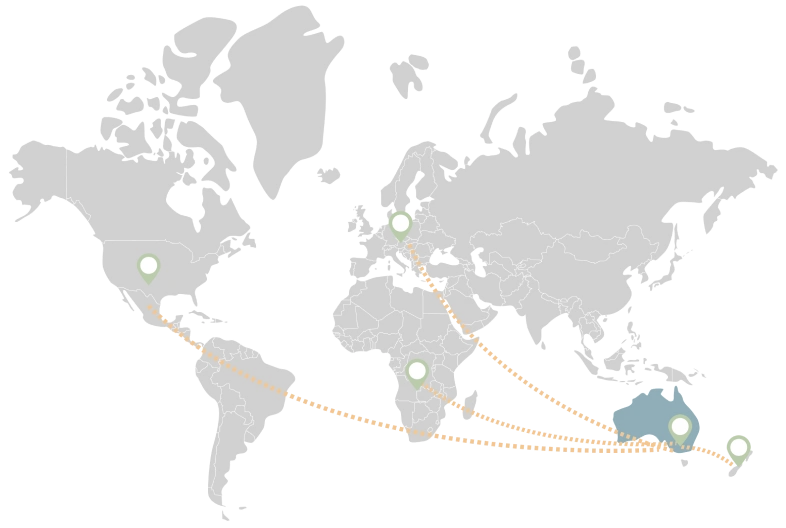

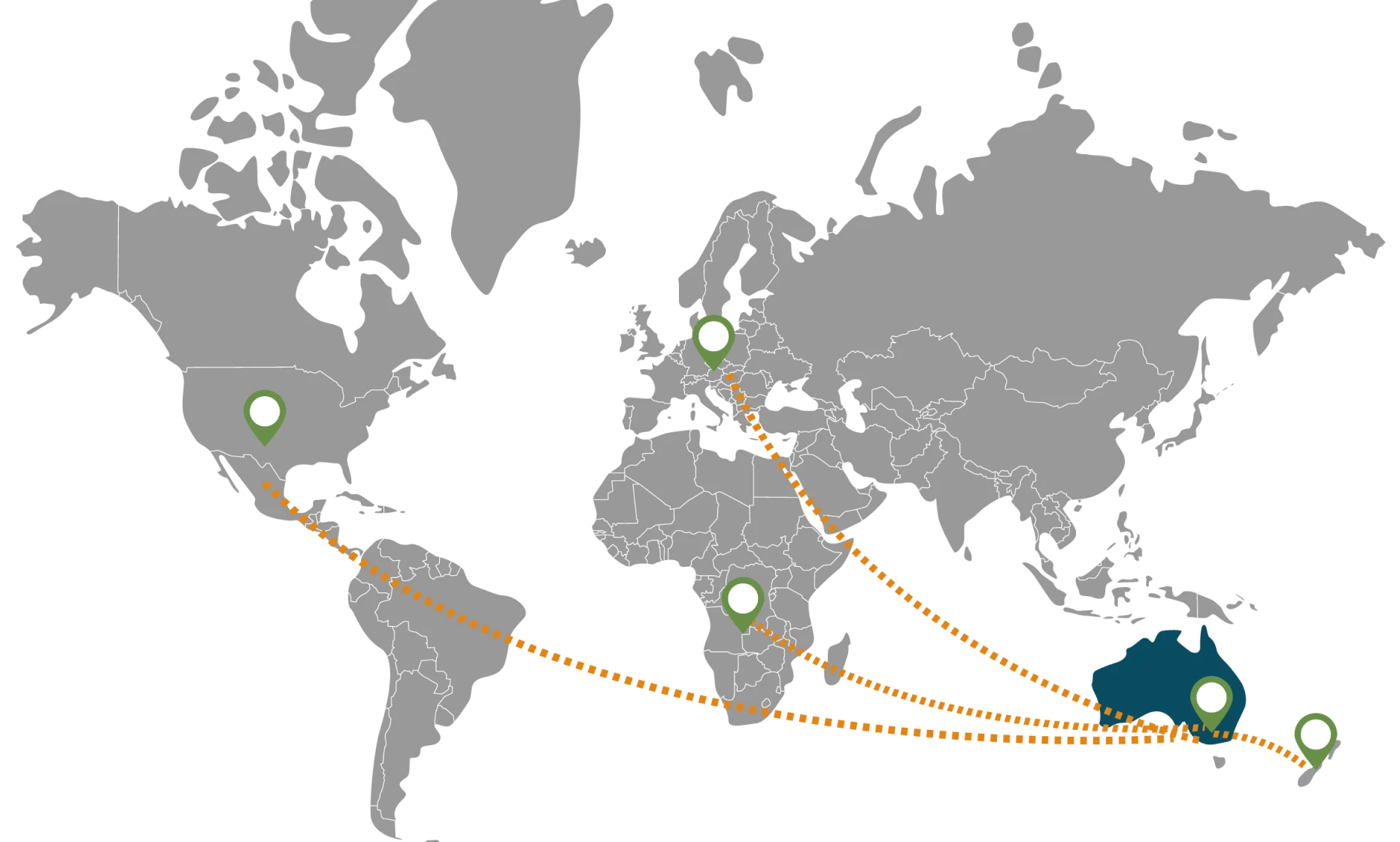

Using a Twin Screw Pump for butter and other food processes make the difference. Get a QTS pump with Advance Pump Systems.

Learn more about our pump solutions

The QTS pump is just one part of our solutions. Learn about our variety of pumps and start implementing them in your industrial applications.