Mixer pumps

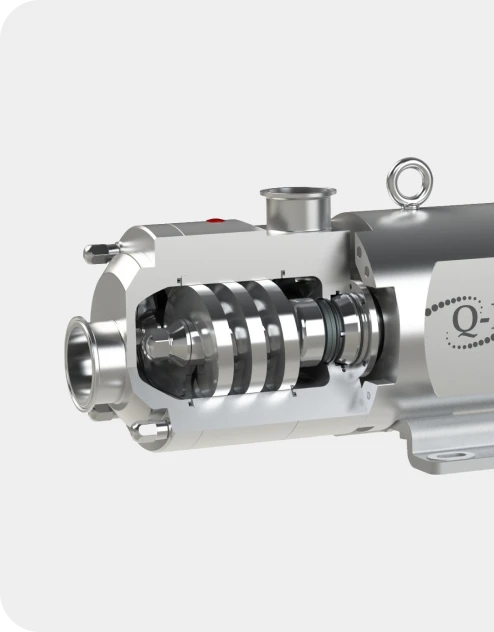

Function and Operation of In-Line Mixers

In-line mixers are advanced solutions designed to deliver versatility and efficiency in industrial processes. Their design allows for the quick and homogeneous integration of liquids and solids, optimising time and ensuring consistent results for various applications.

Key Features of In-Line Mixers

Learn more about the key features of in-line mixers and how they optimise industrial processes.

-

Versatility in Mixing

In-line mixers are designed to blend a wide range of substances, from powders to liquids, offering versatility for various industrial applications. This flexibility ensures that mixers can adapt to different mixing needs, from simple emulsification to more complex particle disintegration.

-

Customisation for Specific Needs

With interchangeable backplates, in-line mixers can be tailored to specific requirements, making them ideal for a variety of applications. Built from high-quality 316L stainless steel, these mixers feature sanitary finishes that ensure cleanliness and durability, even in the most demanding environments.

-

High Efficiency and Low Maintenance

In-line mixers operate with great efficiency, mixing quickly and consistently. Their design makes installation, operation, and maintenance simple, minimising downtime. Additionally, the use of o-rings improves sealing to prevent leaks and ensure optimal performance over time.

Learn About the Different Types of In-Line Mixers

Straight Radial Slots

These backplates are ideal for mixing powders and breaking up lumps, helping to achieve a consistent texture in the final product.

Small Radial Holes

Perfect for applications where emulsification is required, these backplates create smooth, homogeneous mixtures.

Large Radial Holes

Designed to chop soft solids into smaller particles, these backplates facilitate integration into liquid or semi-solid mixtures.

Industries:

-

Chemical

-

Food & Beverages

-

Pharmaceutical

-

Cosmetics &

Personal Care -

Paints & Coatings

-

Adhesives &

Sealants -

Energy & Mining

-

Oil & Gas

-

Agriculture &

Farming -

Wastewater

Treatment

Applications:

-

Chocolate

Production -

Butter Production

-

Cosmetics

Manufacturing -

Pharmaceutical

Formulations -

Food Additives

-

Fruit Juice

Concentrates -

Ice Cream

Production -

Paint Production

-

Cosmetic Creams

-

Lotions & Creams

-

Pet Food

Production -

Animal Feed

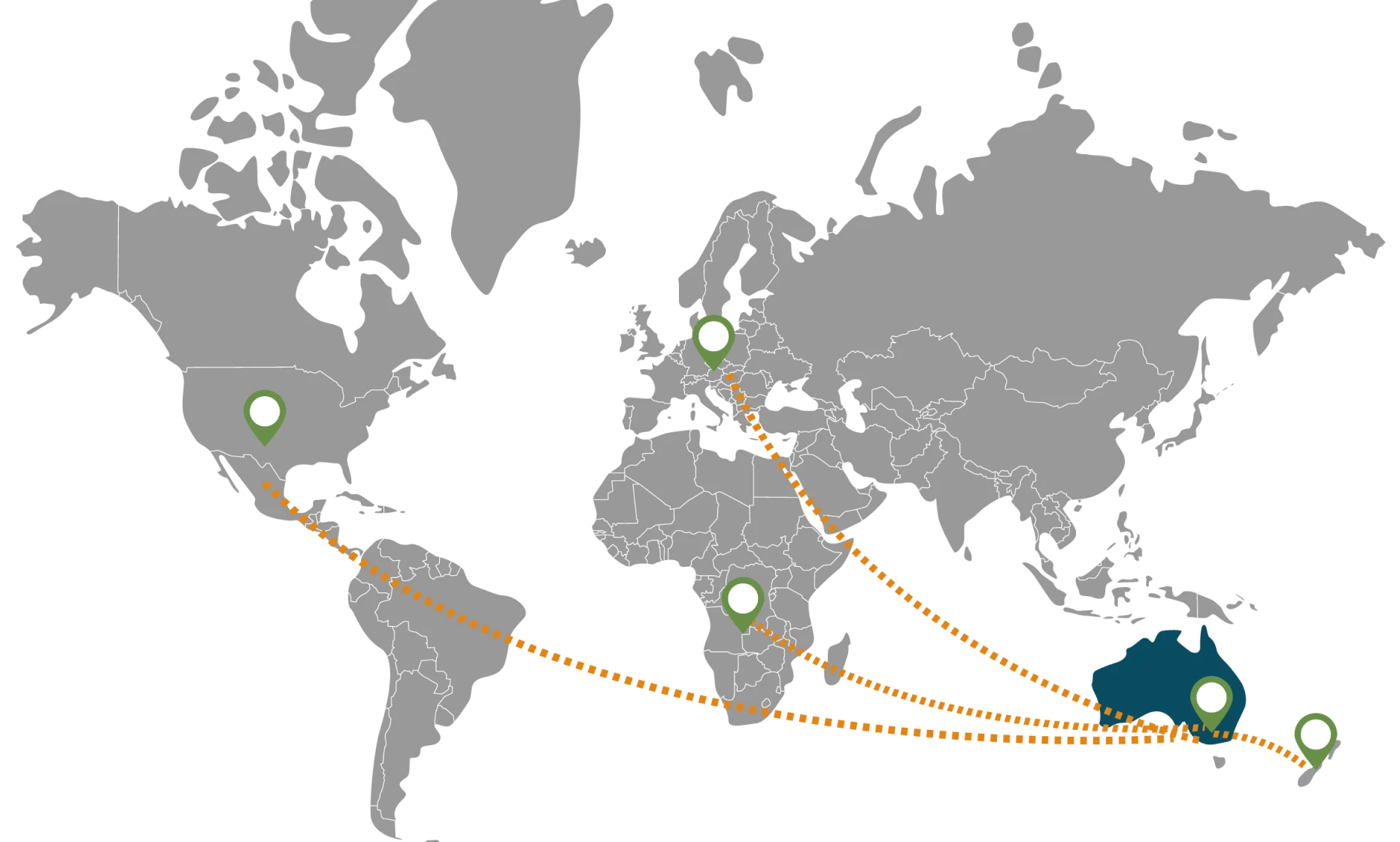

Why Choose Advance Pump Systems as Your Supplier?

With over 20 years of experience, we supply industrial pump solutions across Australia and New Zealand. Our expertise enables us to optimise industrial processes using advanced technologies such as centrifugal pumps, positive displacement pumps, mixers, and drum unloaders.

Get the Best Performance Brands for Mixer pumps With Us

Need a Spare Part for Your Centrifugal Pump? We've Got You Covered

Get the spare part you need with us. Our fully stocked warehouse ensures prompt delivery of spare parts for your pumps.