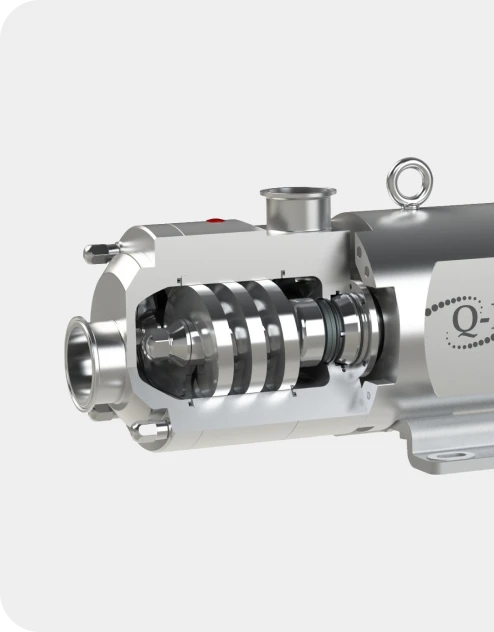

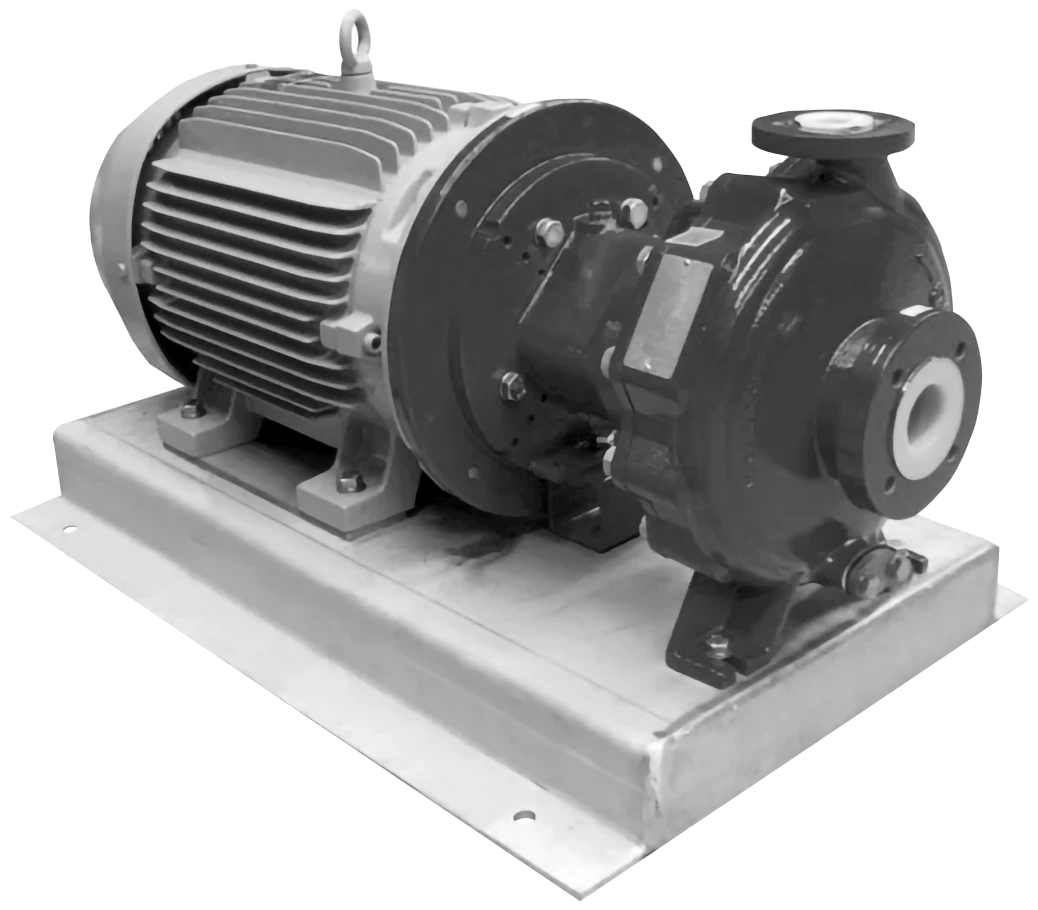

Centrifugal Pumps

Converting Mechanical Energy to Hydraulic Energy

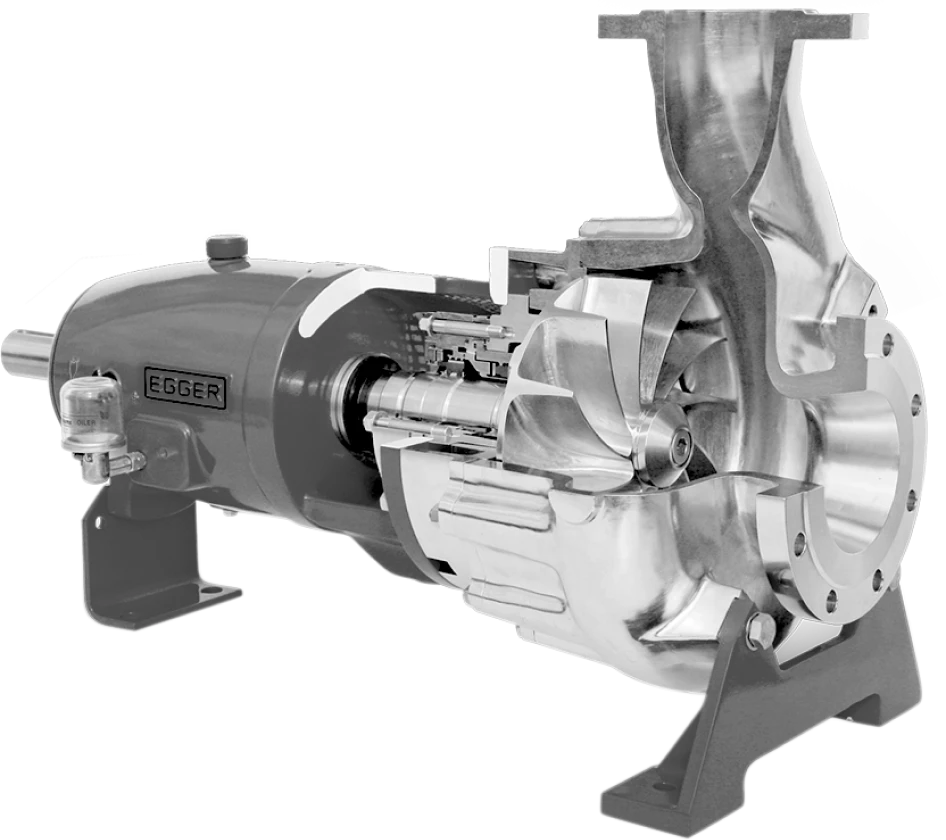

Centrifugal pumps are the most popular and commonly used type of pump for fluid transfer. They are frequently utilised to induce flow or elevate liquids from low to high levels. These pumps operate on a straightforward mechanism, converting rotational energy into energy in a moving fluid.

Centrifugal Pumps' Characteristics

Learn more about centrifugal pumps and their features.

-

Efficiency and Performance

Centrifugal pumps are highly efficient, capable of handling high flow rates and low-viscosity fluids. Their performance depends on factors such as impeller design, rotational speed, fluid properties, and system conditions.

-

Priming Mechanism

These pumps require priming to remove air and create a vacuum for efficient operation, either manually or automatically.

-

Corrosion Resistance

Designed for durability, centrifugal pumps can handle various fluids, including corrosive ones, ensuring extended service life even under heavy use.

-

Durability and Maintenance

While some centrifugal pumps require frequent maintenance, chemical centrifugal pumps have minimal routine maintenance needs, making them cost-effective in the long term.

-

Wide Range of Applications and Versatility

Centrifugal pumps are highly versatile and suitable for numerous industries and applications.

Learn About the Different Types of Centrifugal Pumps

Magnetic Drive

Magnetic drive pumps use magnets to create a seal between the motor and impeller, eliminating the need for a traditional shaft seal. This design prevents leaks and contamination, making them ideal for handling corrosive or hazardous fluids in various industries.

Industry:

- Water

Applications:

-

Chemical

manufacturing -

Water treatment

-

Acids

-

Alkalis

Self-Priming

Self-priming centrifugal pumps can handle air pockets and gas bubbles that typically interrupt fluid flow, unlike traditional models that require the suction line to be filled.

Industry:

- Water

Applications:

-

Water treatment

-

Wastewater

Submersible

Submersible pumps are designed to operate fully submerged in the fluid being pumped. They convert the kinetic energy of a rotating impeller into pressure energy to move fluids.

Industry:

- Water

Applications:

-

Water treatment

-

Wastewater

-

Drainage

Column

Column centrifugal sump pumps are ideal for transferring liquids from sumps or below-ground tanks.

Industry:

- Water

Applications:

-

Water treatment

-

Wastewater

Inline Vertical Multistage

Vertical inline pumps have a compact design with in-line inlet and outlet arrangements, making them suitable for space-restricted environments like ships.

Industry:

- Water

Applications:

-

Water transfer

-

Boiler feed

-

Water heating

-

Cooling

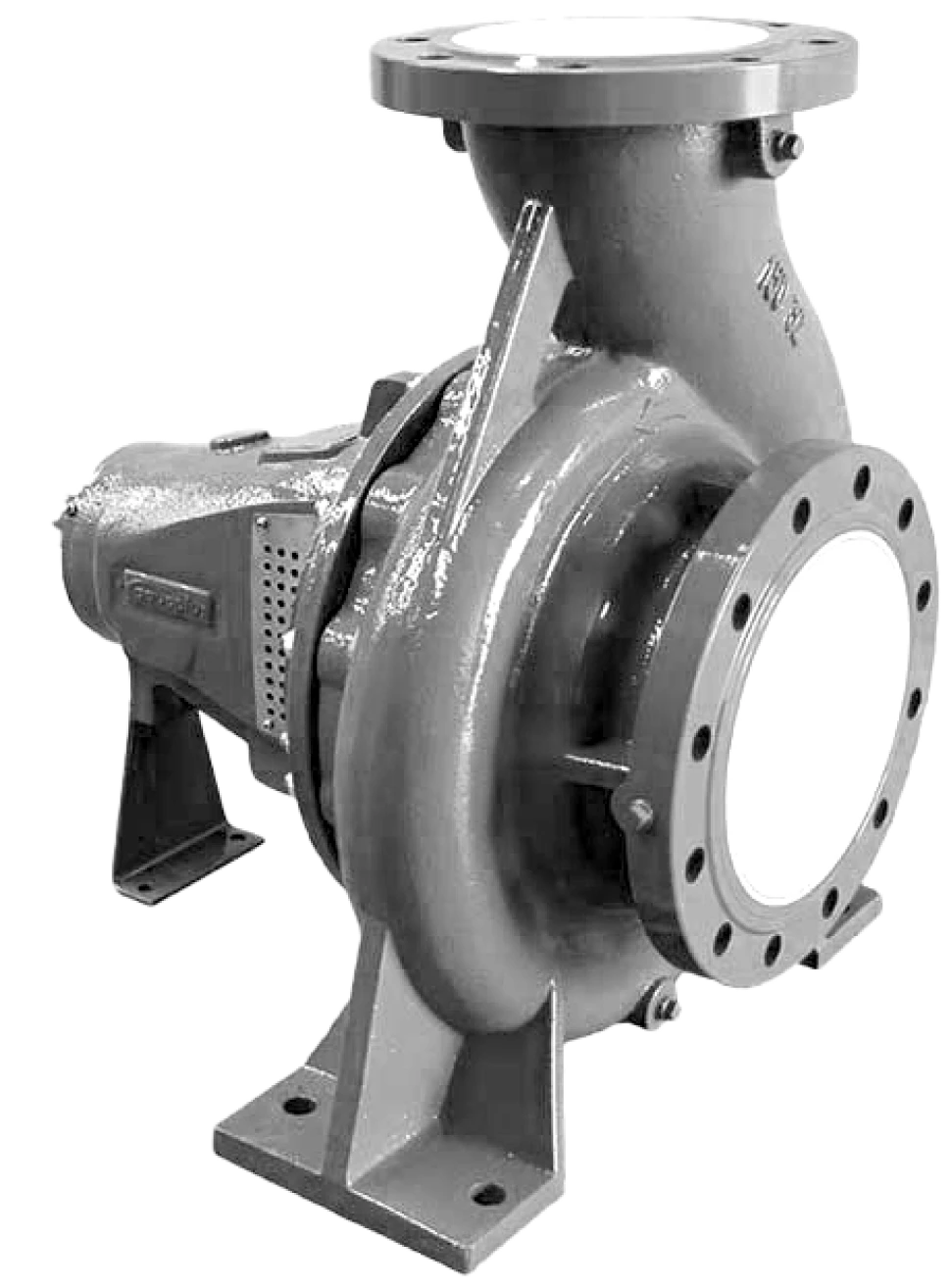

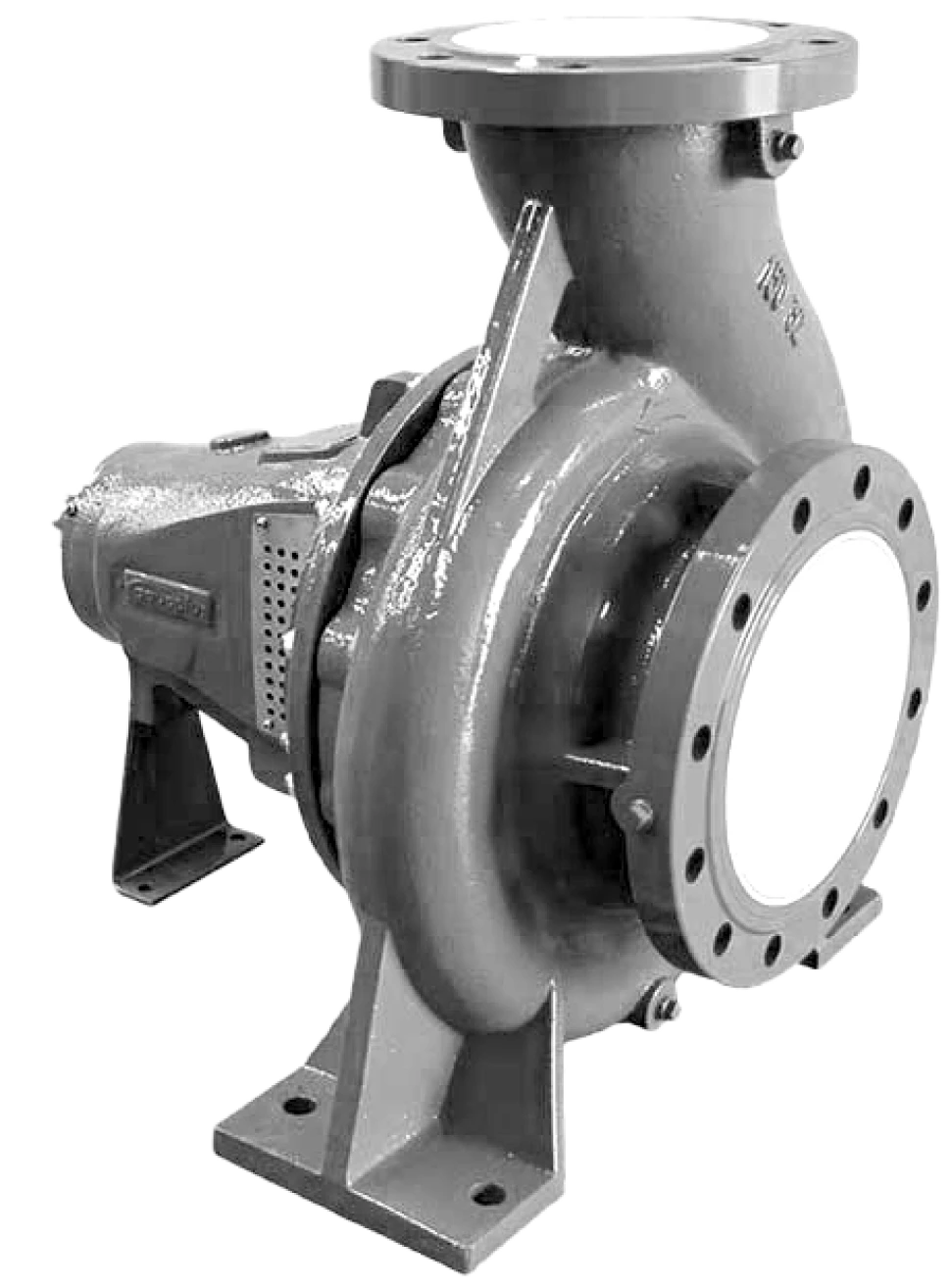

End Suction

End suction pumps are efficient and widely used in various industries.

Industry:

- Water

Applications:

-

Irrigation

-

Water boosting

-

Water transfer

Borehole

Borehole pumps are designed to extract water from underground sources like wells. They are commonly used in residential, agricultural, and industrial applications.

Industry:

- Water

Applications:

-

Water supply

-

Irrigation

-

Mine dewatering

-

Water boosting

Vortex

Vortex pumps operate by generating a swirling flow through a recessed impeller, creating suction for pumping liquids.

Industry:

- Water

Applications:

-

Water treatment

-

Wastewater

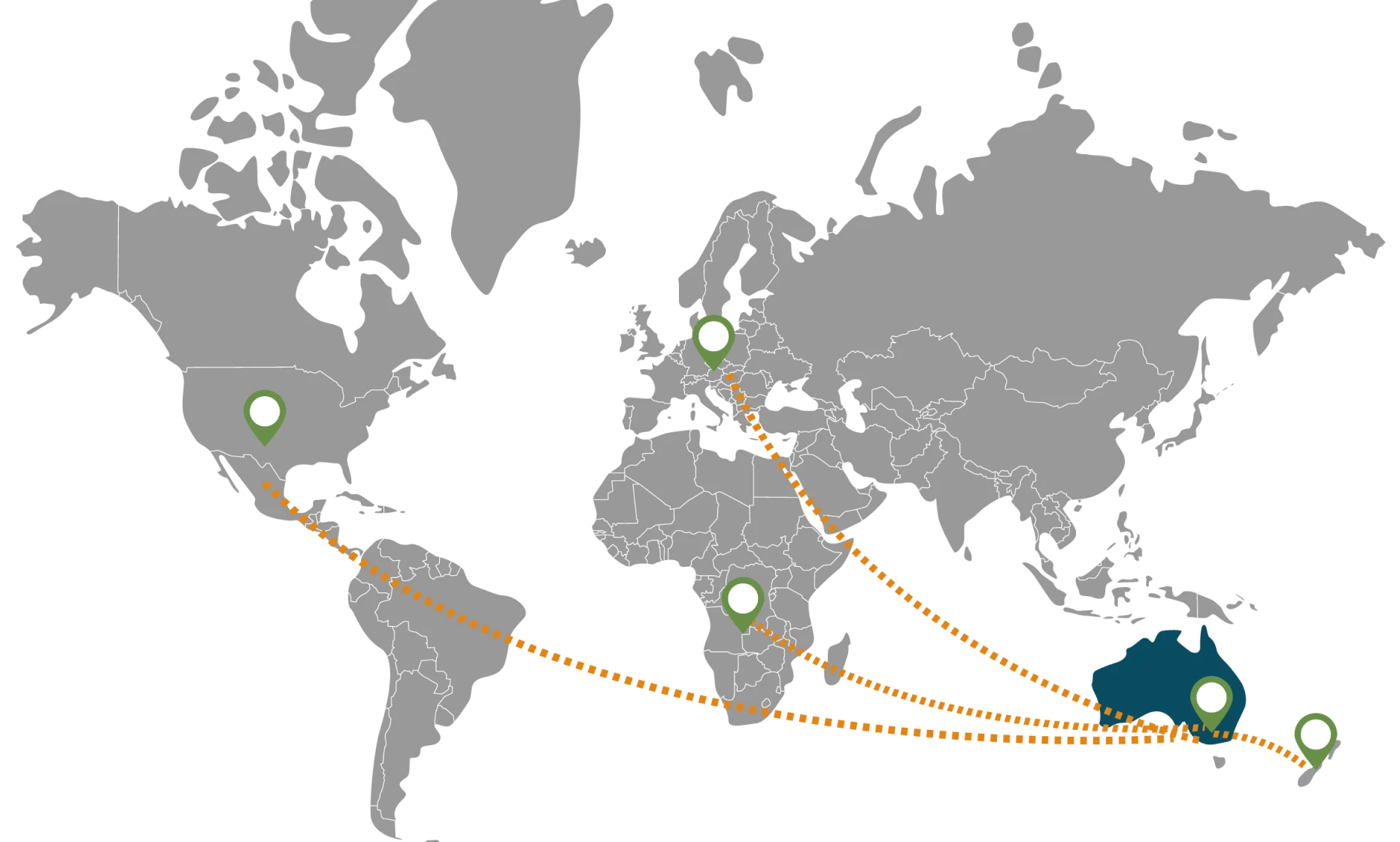

Why Choose Advance Pump Systems as Your Supplier?

With over 20 years of experience, we supply industrial pump solutions across Australia and New Zealand. Our expertise enables us to optimise industrial processes using advanced technologies such as centrifugal pumps, positive displacement pumps, mixers, and drum unloaders.

Get the Best Performance Brands for Centrifugal Pumps With Us

Need a Spare Part for Your Centrifugal Pump? We've Got You Covered

Get the spare part you need with us. Our fully stocked warehouse ensures prompt delivery of spare parts for your pumps.