In the wastewater management industry, selecting the right pump is crucial in the wastewater management industry. The efficiency, durability, and operational costs of pumps can significantly impact the overall performance of treatment facilities and industrial operations. As industries face increasing demands for sustainable and effective wastewater solutions, understanding the various types of pumps available becomes essential.

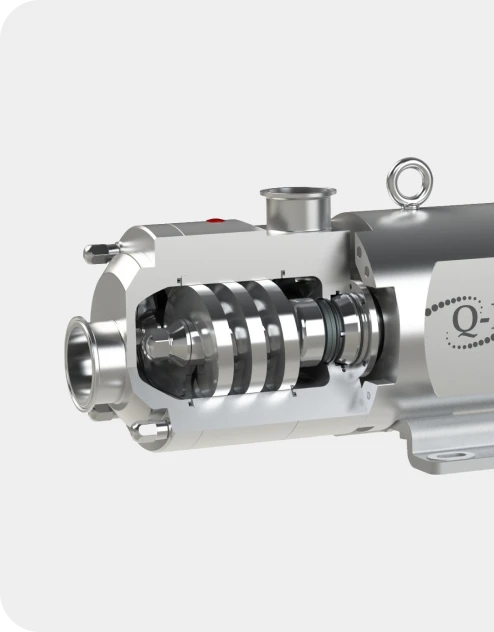

Among the leading solutions, the Centrifugal Pump by Q-Pumps®, provided by Advance Pump Systems in Australia, stands out for their reliability and innovative design.

Among the leading solutions, the Centrifugal Pump by Q-Pumps®, provided by Advance Pump Systems in Australia, stands out for their reliability and innovative design.

Understanding wastewater pumps

Wastewater is originated from the manufacture of specific products. This is usually more concentrated, more variable in content and rate, and requires more extensive or different treatment than domestic wastewater.

Wastewater pumps are designed to move sewage and effluents from one location to another, typically from lower to higher elevations. They play a critical role in municipal wastewater treatment facilities, industrial sites, and agricultural applications. The two primary categories of these kinds of pumps are submersible pumps and centrifugal pumps. Each type has its unique advantages and applications depending on the specific requirements of the job.

Unlike traditional submersible pumps, wastewater pumps are designed to manage liquids with higher density and sludge levels, accommodating solid, fibrous, and abrasive contaminants like sand, clay, or silt. These pumps are also effective for tasks such as clearing flooded basements or clearing rainwater that contains debris. Determining the nature of the water being pumped is essential when choosing the right one.

Centrifugal pumps

Centrifugal pumps are widely used in wastewater applications due to their ability to handle large volumes of liquid. They operate by converting rotational kinetic energy into hydrodynamic energy, which moves the fluid through the pump. These pumps are ideal for transferring wastewater over long distances or to higher elevations. Their versatility makes them suitable for various industrial applications, including food processing, chemical manufacturing, and municipal sewage systems.

Their maintenance is also reasonably straightforward. Centrifugal pumps are ideal for wastewater treatments because they resist clogging, unless there is an issue with the impeller. The moving parts inside one of these pumps are also quite durable, which ensures your pump will last a long time.

Their maintenance is also reasonably straightforward. Centrifugal pumps are ideal for wastewater treatments because they resist clogging, unless there is an issue with the impeller. The moving parts inside one of these pumps are also quite durable, which ensures your pump will last a long time.

Factors to consider when choosing a pump for wastewater

When selecting a pump for wastewater, several factors must be considered to ensure optimal performance:

- Type of wastewater: Different wastewater types require different pumping solutions. For example, municipal sewage may contain solids that necessitate a pump capable of handling larger particles, while industrial wastewater may have specific chemical compositions requiring resistant materials.

- Flow rate requirements: Understanding the required flow rate is essential in selecting a pump. A pump that is too small may not meet the demand, while an oversized pump can lead to energy inefficiencies.

- Head requirements: The total dynamic head (TDH) is a critical parameter in wastewater pumping. It includes both the vertical lift and the friction losses in the piping system. Knowing the TDH ensures the selected pump can effectively transport the wastewater to its destination.

- Material compatibility: The materials used in the pump construction must be compatible with the wastewater being pumped. Corrosive or abrasive materials can lead to pump failure if not appropriately addressed.

- Maintenance and reliability: Selecting a reliable pump that requires minimal maintenance is vital for operational efficiency. Pumps designed with easy maintenance in mind can save significant downtime and costs.

Centrifugal pump for industrial proposes

The QIS Pump, a high-quality, fully stainless steel centrifugal pump known for its hygienic design and its unmatched performance. Tailored for the rigorous demands of the food, beverage, pharmaceutical, and chemical processing industries while offering a versatile solution for various applications.

Why choose Q-Pumps® for wastewater applications

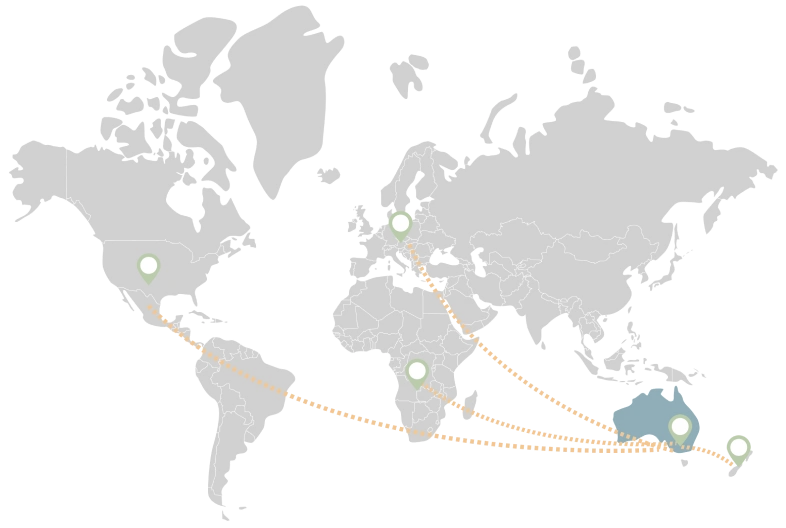

Advance Pump Systems is recognized as a leading provider of industrial pumps in Australia, particularly for their exceptional range of Q-Pumps®. These pumps are engineered with cutting-edge technology to meet the diverse needs of the wastewater industry.

Q-Pumps® are designed for optimal performance under various conditions. Their robust construction ensures longevity, even when handling challenging wastewater applications. With a range of models available, customers can find the perfect pump to suit their specific requirements.

One of the standout features of Q-Pumps® is their innovative design. These pumps incorporate advanced hydraulic technology that maximizes efficiency while minimizing energy consumption. This not only reduces operational costs but also supports sustainability initiatives within industries.

Versatile applications

Whether you are dealing with municipal sewage or industrial effluent, Q-Pumps® provide versatile solutions for diverse applications. Their ability to handle solids, corrosive materials, and varying flow rates makes them an ideal choice for any wastewater project.

Select Advance Pump Systems as your pump supplier in Australia

Advance Pump Systems is committed to providing unparalleled customer support. Their team of experts offers guidance in selecting the right pump for wastewater, ensuring you select the model best suited to your operational requirements. Additionally, they provide ongoing maintenance services to keep your pumps running efficiently.

Selecting the right pump for wastewater is crucial for any industry involved in wastewater management. The efficiency, reliability, and operational costs of the pump directly influence the success of wastewater treatment processes. With a variety of pumps available, understanding your specific requirements and the capabilities of different models is essential.

Advance Pump Systems, with its range of Q-Pumps®, provides unmatched solutions for the wastewater industry in Australia. Their commitment to quality, innovative design, and exceptional customer support makes them the preferred choice for businesses looking to enhance their wastewater management processes.

Whether you're managing municipal sewage or industrial effluent, choosing us as your provider will ensure you have the right equipment to meet your needs efficiently and effectively.

Whether you're managing municipal sewage or industrial effluent, choosing us as your provider will ensure you have the right equipment to meet your needs efficiently and effectively.