In the food and beverage industry, choosing the right pump is essential to maintaining efficiency, product quality, and compliance with strict hygiene standards. Pumps play a crucial role in handling various liquids and solids across different processes. Selecting the most suitable pump type can significantly impact production efficiency and reduce operating costs.

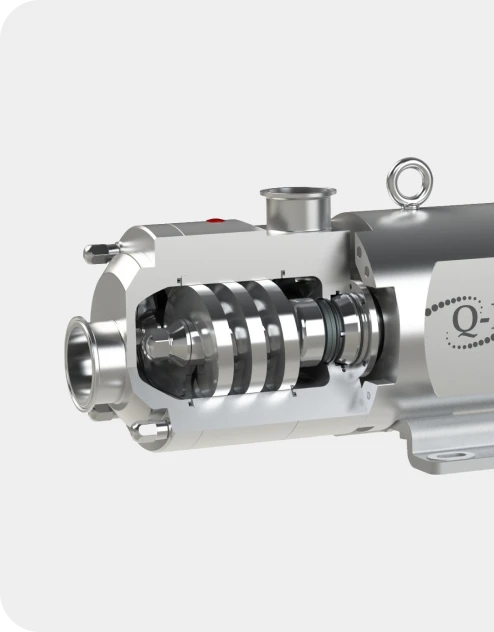

Among the recognized brands in the industry, Q-Pumps® offers a reliable range of solutions known for high-quality engineering and hygienic design, ensuring compatibility with the stringent requirements of the food and beverage sector.

Understanding Hygienic Pumps in the Food and Beverage Industry

Pumps used in food processing must meet strict hygiene and safety standards to prevent contamination and bacterial growth. Hygienic pumps are designed with smooth surfaces, easy-to-clean components, and durable materials to withstand frequent cleaning cycles and corrosive products. Q-Pumps® is highly regarded for its commitment to these standards, offering pumps made from high-quality stainless steel 316L and innovative designs.

Two of the most commonly used pump types in food and beverage processing are centrifugal pumps and positive displacement pumps. Each type has unique benefits depending on application needs, such as viscosity, flow rate, and shear sensitivity.

Types of Pumps for Hygienic Applications

1. Centrifugal Pumps

Centrifugal pumps are widely used in applications with low-viscosity liquids, such as water, juices, and milk. They work by converting the kinetic energy from a rotating impeller into fluid flow, making them ideal for moving large volumes over short distances. Centrifugal pumps are valued for their efficiency and easy maintenance, with fewer moving parts that reduce downtime. Q-Pumps® offers centrifugal pumps designed to withstand the demanding environments of food and beverage processing, combining performance with compliance.

2. Positive Displacement Pumps

Positive displacement pumps, including types such as lobe, gear, and peristaltic pumps, are ideal for handling thicker, more viscous products like syrups, creams, and pastes. These pumps transfer a fixed volume per rotation, providing a steady flow regardless of pressure variations. Positive displacement pumps are gentle on sensitive products, making them ideal for handling ingredients such as dairy, sauces, and certain beverages without compromising product integrity. Q-Pumps® offers a variety of positive displacement pumps specifically designed for these applications, ensuring smooth and precise transfer.

Key Factors to Consider When Selecting a Pump

Choosing the right pump for food and beverage processing involves several factors. Here are some of the most critical aspects to consider:

• Product Compatibility

It is essential that the pump materials are compatible with the specific liquid or solid being processed. Corrosive or acidic products, such as certain juices or sauces, require pumps made with resistant materials like stainless steel 316L to avoid damage. Q-Pumps® manufactures its pumps with durable materials to ensure compatibility with a wide range of food products.

• Flow Rate and Pressure Requirements

Each process has unique flow and pressure needs. Centrifugal pumps are ideal for high flow rates, while positive displacement pumps are suited to low-flow, high-viscosity applications. Q-Pumps® offers models that meet both needs, allowing processors to choose the pump type best suited to their production demands.

• Cleaning and Maintenance

In food processing, pumps often need to comply with Clean-in-Place (CIP) or Sterilize-in-Place (SIP) standards to allow internal cleaning without disassembly. Q-Pumps® designs its pumps with easy-to-clean components, minimizing downtime and maintaining hygiene standards.

Why Choose Q-Pumps® for Food and Beverage Applications?

Q-Pumps® has established itself as a leading manufacturer for the food and beverage industry, providing pumps that meet the sector’s demanding standards for hygiene, durability, and performance. Their pumps are designed to deliver reliable performance, even in challenging applications. With a diverse selection of models available, Q-Pumps® ensures that customers can find the ideal solution for their unique production needs.

A standout feature of Q-Pumps® products is their commitment to efficiency and sustainability. Through innovative hydraulic design, these pumps optimize energy use, helping to reduce operating costs and support environmental goals in food and beverage production.

Versatile Applications

Whether handling liquid, solid, or viscous ingredients, Q-Pumps® offers versatile solutions suitable for the diverse demands of food and beverage processing. With the ability to handle various textures and flow requirements, these pumps are a valuable choice for companies seeking to enhance productivity without compromising quality.

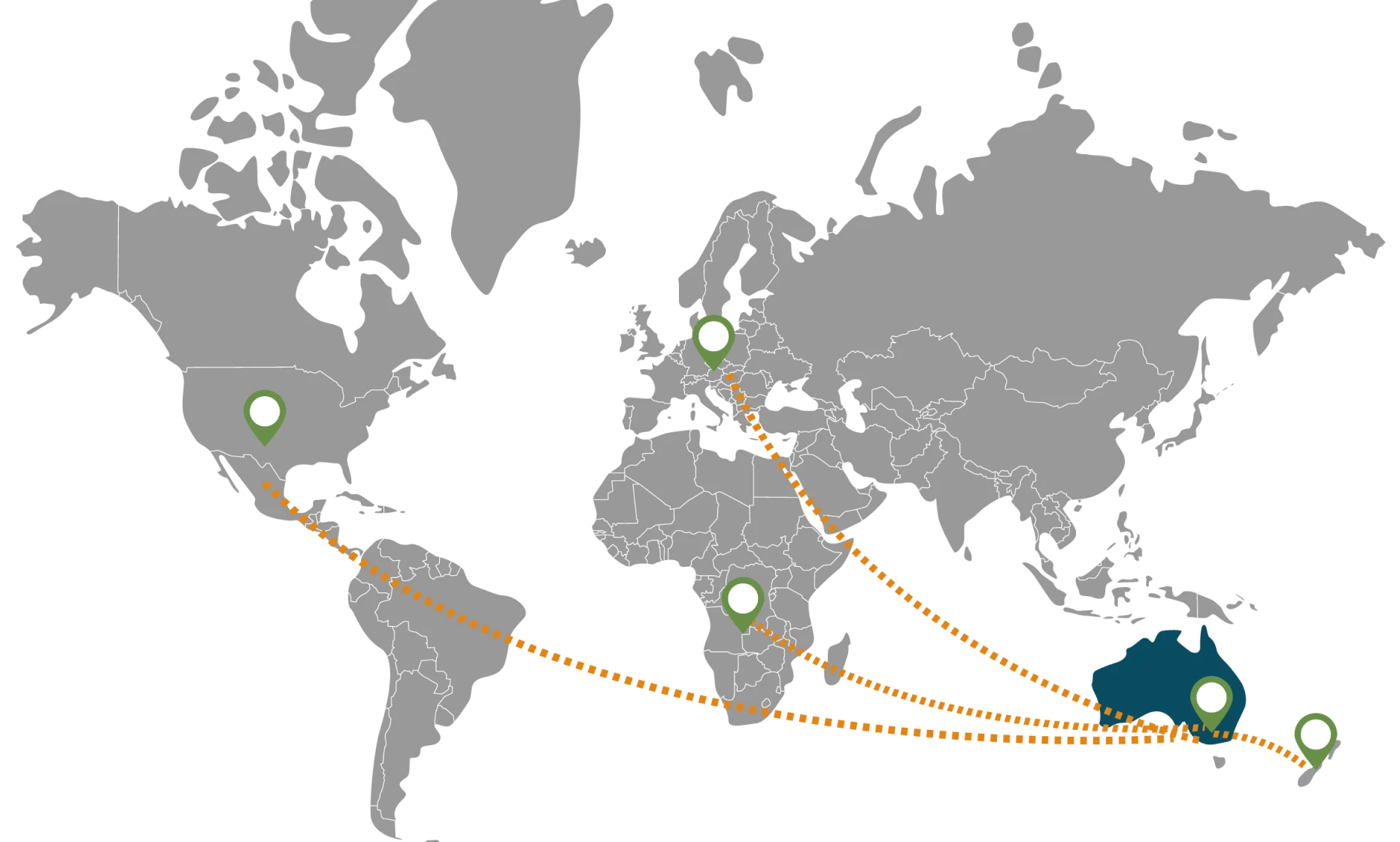

Choose Advance Pump Systems as Your Pump Supplier in Australia

Advance Pump Systems offers exceptional support and expertise in pump selection, providing a complete range of Q-Pumps® products tailored to the Australian market. Their team assists in identifying the best pump models for each application and offers ongoing support to keep equipment operating at peak performance.

For companies in the food and beverage industry, selecting a reliable pump supplier is essential. By choosing Advance Pump Systems and Q-Pumps®, you’ll have access to industry-leading technology, excellent customer service, and customized solutions for every stage of production.