Centrifugal pumps are one of the most widely used pieces of equipment in industries across Australia. From mining and agriculture to wastewater treatment and manufacturing, their efficiency and versatility make them indispensable. In this guide, we’ll explore everything you need to know about centrifugal pumps, their applications, and why Advance Pump Systems is your go-to partner for all pumping solutions.

What are centrifugal pumps?

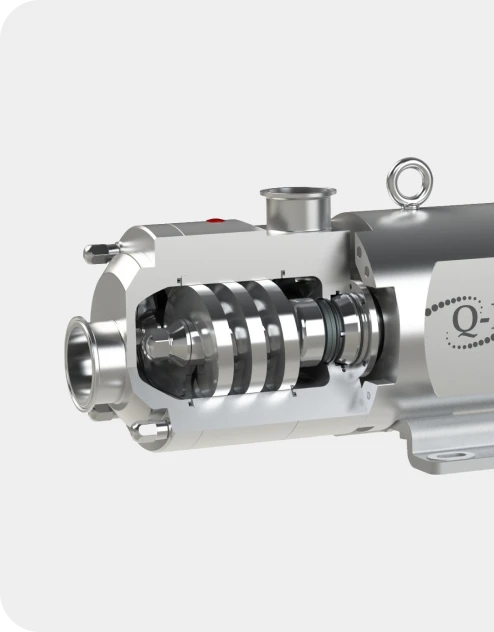

Centrifugal pumps are mechanical devices designed to move fluids by converting rotational energy from a motor into hydrodynamic energy. This process involves a spinning impeller that creates centrifugal force, pushing liquid through the pump and out of its discharge port. Their simplicity, reliability, and ability to handle a wide range of flow rates make them a preferred choice for Australian industries.

Key applications of centrifugal pumps in Australia

Centrifugal pumps have diverse applications across various sectors in Australia:

- Agriculture: Used for irrigation systems and transferring water to farmlands efficiently.

- Mining: Essential for dewatering operations and transporting slurries.

- Water treatment: Crucial in municipal and industrial water supply systems.

- HVAC systems: Provide reliable cooling and heating solutions in commercial and industrial buildings.

- Manufacturing: Support production processes by transferring chemicals, oils, and other fluids.

Advance Pump Systems offers customised centrifugal pump solutions tailored to meet the unique needs of these industries. Contact us today to discuss your project requirements.

How do centrifugal pumps work?

The working principle of centrifugal pumps is relatively simple yet highly effective:

- Fluid enters the pump: The liquid is drawn into the pump through the suction inlet.

- Impeller rotation: The motor drives the impeller, which spins at high speed.

- Energy transfer: The impeller’s rotation imparts kinetic energy to the fluid, increasing its velocity.

- Discharge: The pump’s casing converts the high-velocity energy into pressure, forcing the fluid out through the discharge port.

To ensure optimal performance, it’s crucial to select the right pump size and type for your application. At Advance Pump Systems, our experts can guide you through the selection process to ensure maximum efficiency.

Benefits of centrifugal pumps

When you choose centrifugal pumps, you gain access to numerous advantages:

- High efficiency: Ideal for transferring large volumes of liquid quickly.

- Cost-effective: Low operational and maintenance costs.

- Versatility: Suitable for various liquids, including water, chemicals, and slurries.

- Ease of maintenance: Minimal moving parts simplify servicing and repairs.

Factors to consider when choosing a centrifugal pump

Selecting the right centrifugal pump requires careful consideration of factors such as:

- Flow rate: The volume of liquid to be pumped per unit of time.

- Head pressure: The total pressure the pump must overcome to move the fluid.

- Liquid properties: Viscosity, temperature, and chemical composition of the fluid.

- Pump material: Ensure compatibility with the liquid to avoid corrosion or damage.

Advance Pump Systems provides a comprehensive range of centrifugal pumps to suit any application. Whether you need assistance with pump selection or installation, our team is here to help.

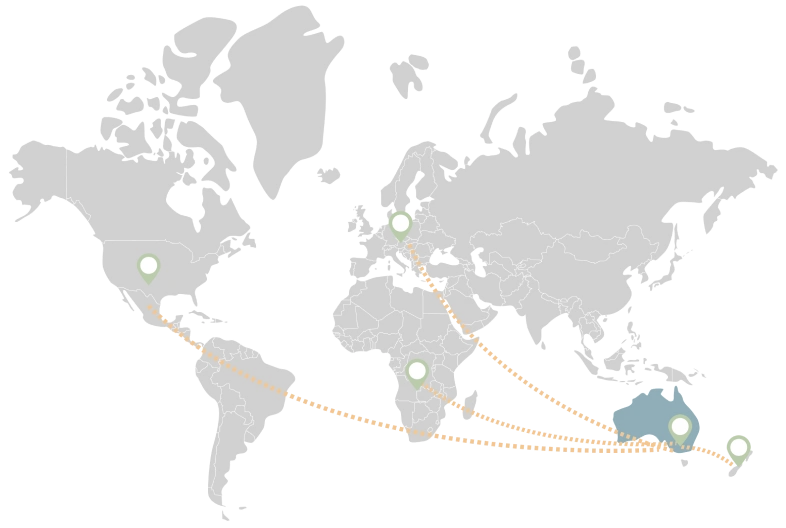

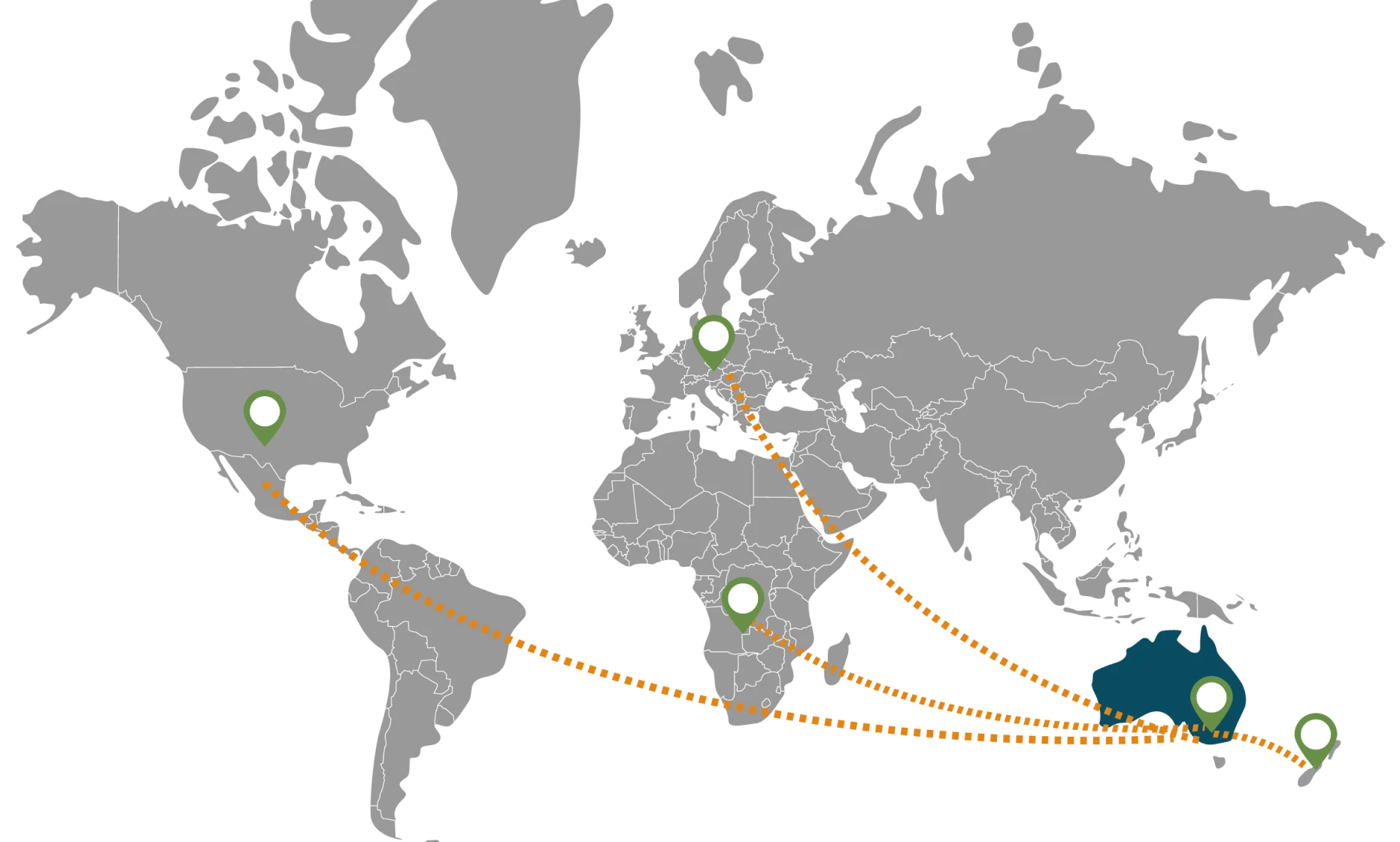

Why choose Advance Pump Systems for centrifugal pumps in Australia?

At Advance Pump Systems, we pride ourselves on delivering top-notch centrifugal pump solutions. Here’s why we’re the trusted choice for Australian businesses:

- Quality products: We source pumps from leading global manufacturers.

- Customised solutions: Tailored to meet your specific operational needs.

- Reliable support: From selection to installation and maintenance, we’ve got you covered.

Ready to optimise your operations with the right centrifugal pump? Get in touch with us to explore our solutions.

Maintenance tips for centrifugal pumps

To ensure long-lasting performance, regular maintenance is essential. Here are some tips:

- Inspect seals and bearings: Prevent leaks and ensure smooth operation.

- Monitor performance: Check for unusual noise or vibrations.

- Clean components: Remove debris from the impeller and casing.

- Schedule servicing: Professional inspections can identify potential issues early.

Advance Pump Systems offers comprehensive maintenance services to keep your pumps in top condition. Learn more here.

Centrifugal pumps are a cornerstone of many industries in Australia, offering efficiency, reliability, and versatility. Whether you’re in agriculture, mining, or water treatment, having the right pump can make all the difference. At Advance Pump Systems, we provide expert guidance, high-quality products, and unmatched support to meet your pumping needs.

Don’t settle for less when it comes to centrifugal pumps in Australia. Contact Advance Pump Systems today and let us help you find the perfect solution for your operations.